AVAILABLE ACCREDITATIONS

Additive

Manufacturing

Aero Structure

Assembly

Aerospace Quality

System

Chemical

Processing

Coatings

Composites

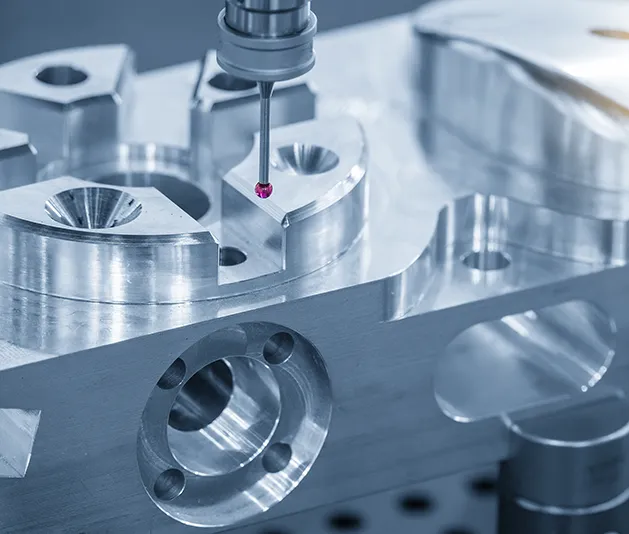

Conventional

Machining

Elastomer

Seals

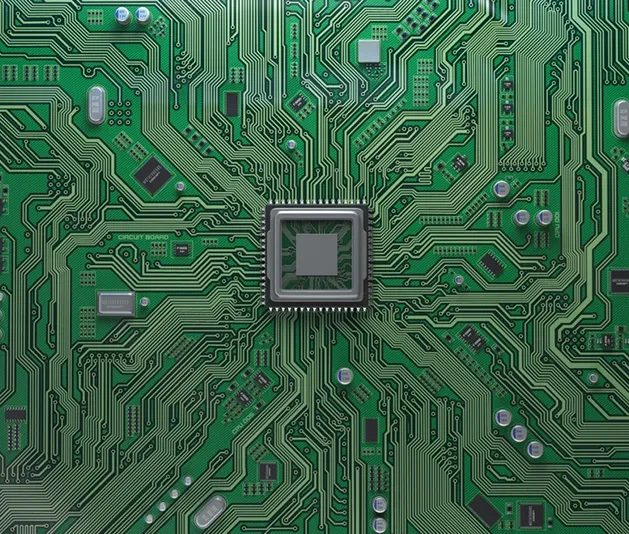

Electronics

Cable and Harness Assemblies

Electronics

Printed Board Assemblies

Electronics

Printed Boards

First Article

Inspection

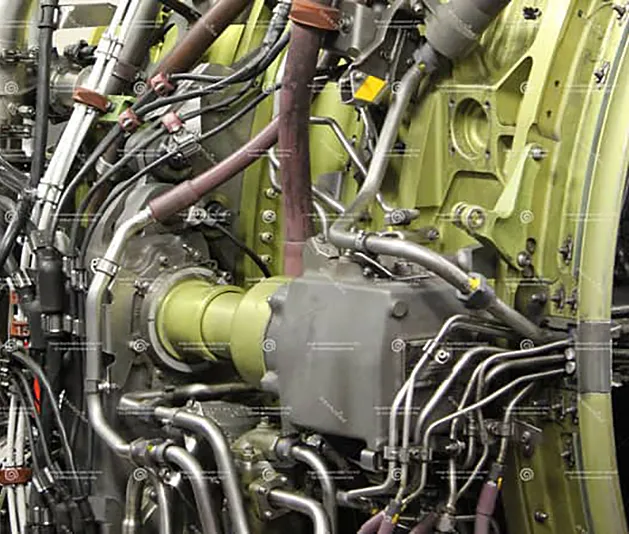

Fluid Distribution

Systems

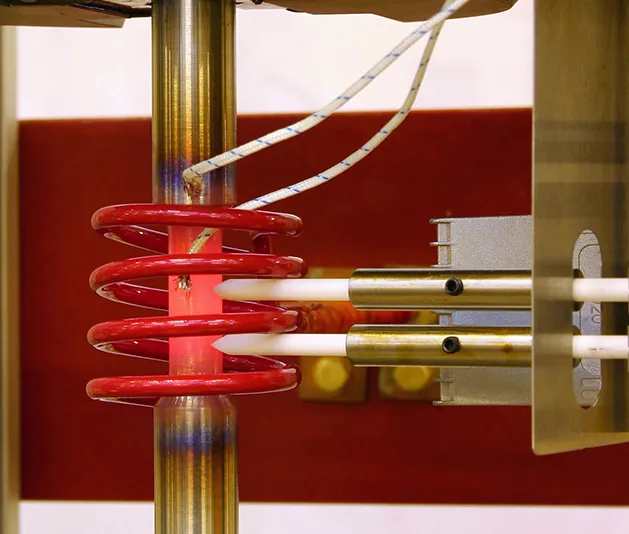

Heat

Treating

Materials Testing

Laboratories

Measurement

& Inspection

Metallic Materials

Manufacturing

Non Metallic

Materials Manufacturing

Non Metallic

Materials Testing

NonDestructive

Testing

Nonconventional

Machining

Sealants

Surface

Enhancement

Welding

Manufacturing

Assembly

System

Processing

Machining

Seals

Cable and Harness Assemblies

Printed Board Assemblies

Printed Boards

Inspection

Systems

Treating

Laboratories

& Inspection

Manufacturing

Materials Manufacturing

Materials Testing

Testing

Machining

Enhancement

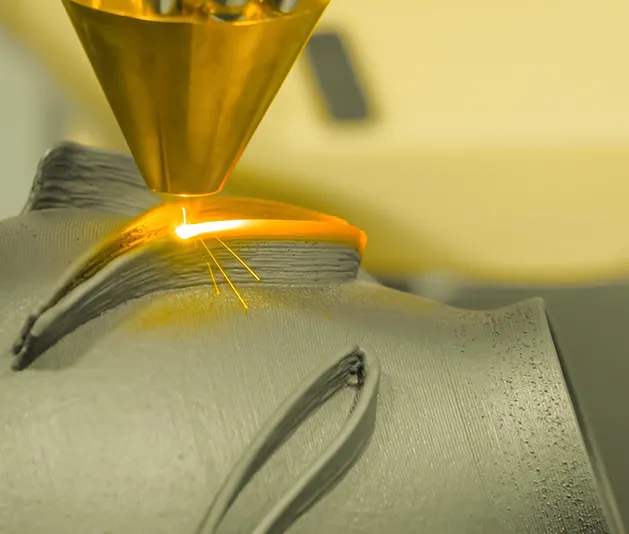

This task group grants accreditation for: Laser (L-PBF) and Electron Beam Powder Bed Fusion (E-PBF) AM processes (currently under Welding Accreditation). Future technologies include Directed Energy Deposition (DED) & Binder Jetting and Manufacture of AM Materials.

This task group focuses on the assembly of aircraft components and grants accreditation for Fastening, Electrical Bonding, Bushing & Bearing Installation and Sealing of Aero Structure Assemblies & Components.

This task group was established as a cost-effective alternative to a supplier having 9100 accreditation. The audit criteria is based off 9100 requirements and is recognized by Nadcap Commodities as a valid quality system. AQS audit criteria is conducted in conjunction with a commodity audit. AQS is an accreditation as a standalone quality system.

This task group is one of the largest commodities and grants accreditation for: Painting, Dry Film Coatings & Sol Gel as Preparation for Paint, Etch Inspection Processes & Pre-Penetrant Etch, Surface Preparation for Metal Bond, Solution Analysis & Testing, Chemical Milling and Alpha Case Removal, Cleanliness Verification, Vacuum Cadmium & Aluminum Ion Vapor Deposition, Anodizing, Electroplating & Electroforming

Electroless Plating, Conversion Coating, Standalone Cleaning, Descaling, Passivation & Electropolishing, Brush Anodizing & Plating and Stripping of Coatings as a Subcontract process.

This task group grants accreditation for Thermal Spray, Vapor Deposited Coatings, Diffusion Coating Processes, Stripping of Coated Materials, Coating Evaluations, Plating of Coated Parts, Heat Treating for Suppliers of Coatings and Grinding of Coatings as a Special Process.

This task group grants accreditation for Compression Molding, Core Processing, Kitting Service Provider, Liquid Resin Processing, Metal Bond and Prepreg/Adhesive Bonding/Resin Film Infusion.

This task group grants accreditation for Holemaking Process, Broaching, Turning, Milling, Grinding and Edge Treatment.

This task group grants accreditation for: Molded Rings & Compression Seals, Molded In-Place Gaskets/Plate Seals, Fabric/Textile Reinforced and Compounding.

This task group group grants accreditation for: Wire Preparation and Stripping, Soldering, Crimping, Insulation Displacement Connection, Splices, Connectorization, Molding, Potting, Cable Assemblies/Wire Measurement, Coax and Twinax, Wire Bundle Securing, Electrical Shielding, Protective Coverings, Finished Assembly and Solderless Wrap.

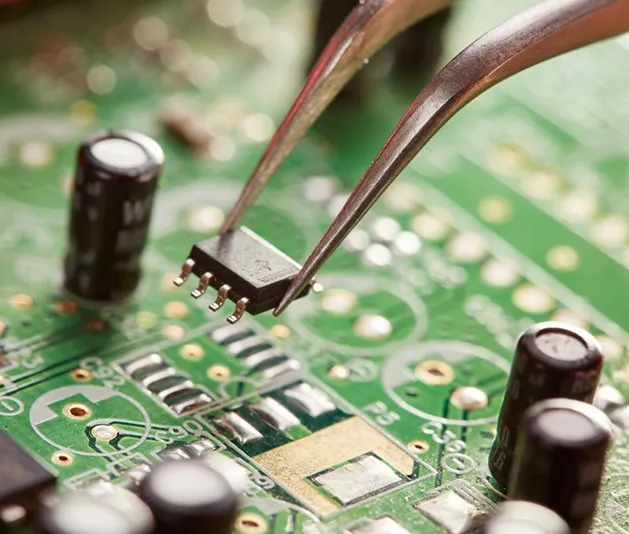

Printed board assemblies (PBA) is not a single process but the entire manufacturing sequence. Each assembly is comprised of multiple processes and is built in accordance with the Class 3 requirements of the J-STD-001 standard. The standard addresses materials, methods and acceptance criteria for producing soldered electrical and electronic assemblies. The intent of the document is to rely on process control methodology to ensure consistent quality levels during the manufacture of products and covers:

- Chemical Process – cleaning, solution control

- Heat treat – reflow soldering

- Coatings – conformal coat (spray, dip, or CVD)

- NDT – X-ray inspection (hidden solder joints – BGA/BTCs)

- Weld – soldering

- Electronics – electrostatic discharge, moisture-sensitive devices

This task group grants accreditation for: Flexible & Rigid Flexible Printed Boards and Electronics High Frequency Printed Boards.

This task group reviews completed FAI reports, to ensure proper form completion, personnel qualifications, requirement flow down, etc.

This task group grants accreditation for: Hose Manufacturing, Fittings and Other Machined Components, Coupling and Formed Sheet Metal Components, Hose Assembly, Titanium 3A1-2.5V Alloy, Seamless Hydraulic Tubing Manufacturing Requirements, Tube Fabricated Assemblies and Value Added Hose Assembly Distributors.

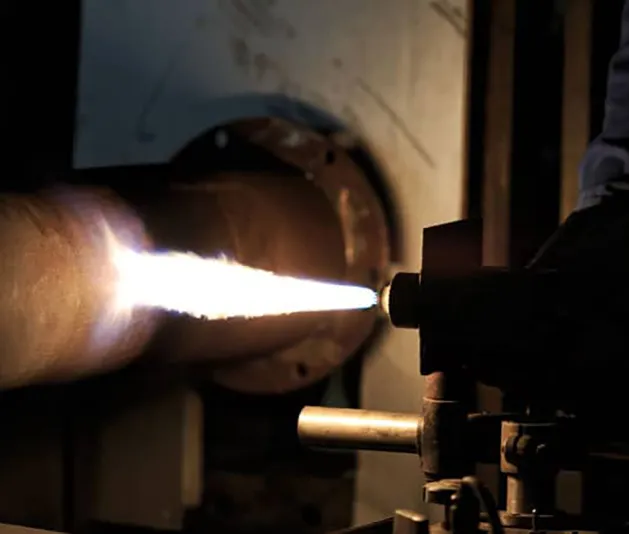

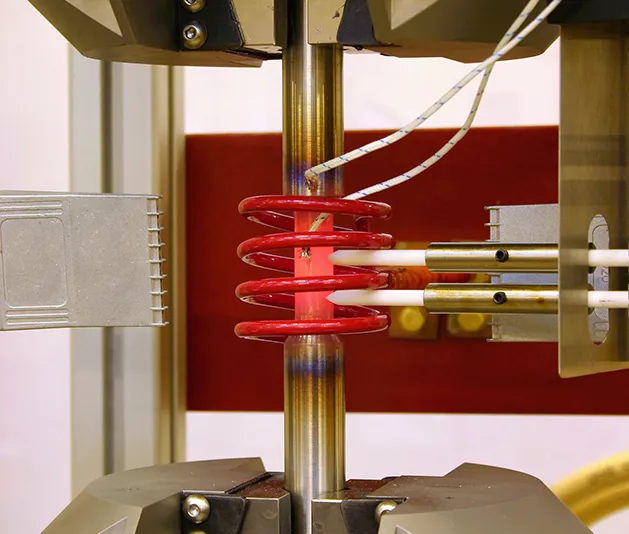

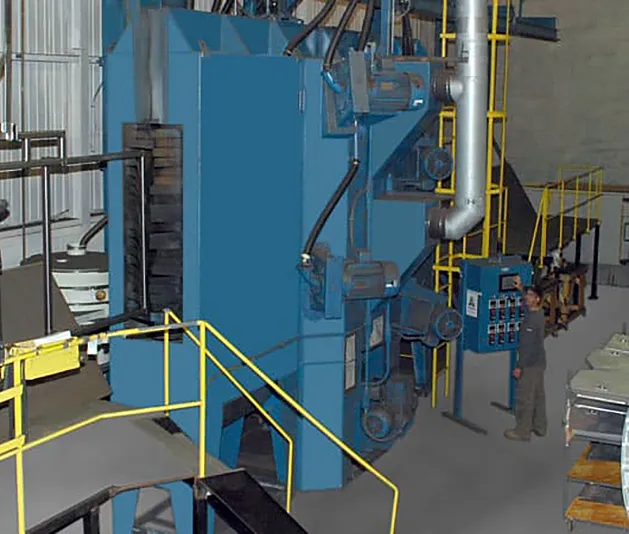

This task group is one of the largest commodities and grants accreditation for Brazing, Carburizing, Gas/Ion/Plasma and/or Salt Bath Nitriding, Hardness and/or Conductivity Testing, Hot Isostatic Pressing (HIP), Induction Hardening, Heat Treating Pyrometry, Sintering & Metal Injection Molding and Localized Heat Treating.

This task group grants accreditation for: Chemical Analysis, Mechanical Testing, Metallography & Microindention Hardness, Hardness Testing (Macro), Corrosion Testing, Mechanical Testing Specimen Preparation, Specimen Heat Treating and Fastener Testing.

This task group grants accreditation for: Coordinate Measuring Machines (CMM),

Laser Tracker, Articulating Arm, Three Dimensional Structured Light Systems (3DSL), Mass Airflow Measurement of Turbine Engine Parts and Accreditation Program General Inspection.

This task group grants accreditation for: Forgings/Castings Hammer, Hydraulic Press, Isothermal Press, Mechanical Press, Radial Forge, Ring Roll and Screw Press.

- CASTINGS

- Sand casting/mechanical and chemical testing/post cast processing/casting process/mold preparation/purchase order review/purchasing and verification of product

- FORGINGS

- Accreditation of the forgings disciplines of open die, closed die, ring rolling, isothermal, hammer, press, extrusion, heat treating equipment and the associated controls and key alloy systems: steel, nickel, titanium and aluminum.

This task group grants accreditation for: Resin Manufacturing, Thermoset Prepreg Manufacturing, Adhesive Film Manufacturing, Core Manufacturing, Fiber Manufacturing and Thermoplastic Prepreg Manufacturing.

This task group grants accreditation for: Physical Testing, Mechanical Testing, Chemical Testing, Thermal Analysis and Flammability

[designed as part of this accreditation, as subset]

Pertaining to:

- Material Testing

- Composites/Adhesive/Adhesive Primer/Elastomers/Core/Fiber

- Fabrication

- PanelFab /Specimen Fab /Specimen Machining

This task group grants accreditation for: penetrant, magnetic particle, ultrasonic, film radiography, eddy current, digital detector array or computed radiology.

This task group grants accreditation for: Electrochemical Drilling, Electrochemical Grinding, Electrical Discharge Machining, Laser Part Marking, Spark Erosion Grinding and Abrasive Water Jet Machining.

The SLT Task group grants accreditation for:

- Sealant Manufacturers

- Bulk Kits

- Repackagers

- Container Kits

- Injection Kits and One-Part Cartridge

- Mix on Demand Kits

- PMF

- PMF Seals

This task group grants accreditation for: Shot Peening, Peen Forming, Glass Bead Peening, Peen Forming, Flapper, Manual, Automated and Computer Controlled.

This task group grants accreditation for: Brazing (Torch/Induction), Flash Welding, Electron Beam Welding, Welding (Spot, Seam, Projection), Resistance Welding (Spot, Seam, Projection), Fusion Welding, Laser Welding, Friction/Inertia Welding, Diffusion, Welding, Stud Welding, Welder/Welding Operator Qualification, Evaluation of Welds and

Laser & Electron Beam Metallic Powder Bed Additive Manufacturing.

- ADDITIVE MANUFACTURING

- AERO STRUCTURE ASSEMBLY

- AEROSPACE QUALITY SYSTEM

- CHEMICAL PROCESSING

- COATINGS

- COMPOSITES

- CONVENTIONAL MACHINING AS A SPECIAL PROCESS

- ELASTOMER SEALS

- ELECTRONICS – CABLE AND HARNESS ASSEMBLIES

- ELECTRONICS – PRINTED BOARD ASSEMBLIES

- ELECTRONICS – PRINTED BOARDS

- FIRST ARTICLE INSPECTION

- FLUID DISTRIBUTION SYSTEMS

- HEAT TREATING

- MATERIALS TESTING LABORATORIES

- MEASUREMENT & INSPECTION

- METALLIC MATERIALS MANUFACTURING

- NON METALLIC MATERIALS MANUFACTURING

- NON METALLIC MATERIALS TESTING

- NONDESTRUCTIVE TESTING

- NONCONVENTIONAL MACHINING

- SEALANTS

- SURFACE ENHANCEMENT

- WELDING